For industries that require storage solutions, such as chemical manufacturing, food and beverage processing, and pharmaceuticals, the choice of material for containers and tanks is critical. Stainless steel tanks have emerged as a frontrunner due to their reliability and numerous advantages over other materials.

Their resistance to corrosion, durability, and ease of cleaning make them an excellent choice for a wide range of applications. Below, we explore the myriad benefits that these sturdy containers provide to industries that prioritize safety, purity, and efficiency. Keep reading to discover why stainless steel tanks are the preferred storage option.

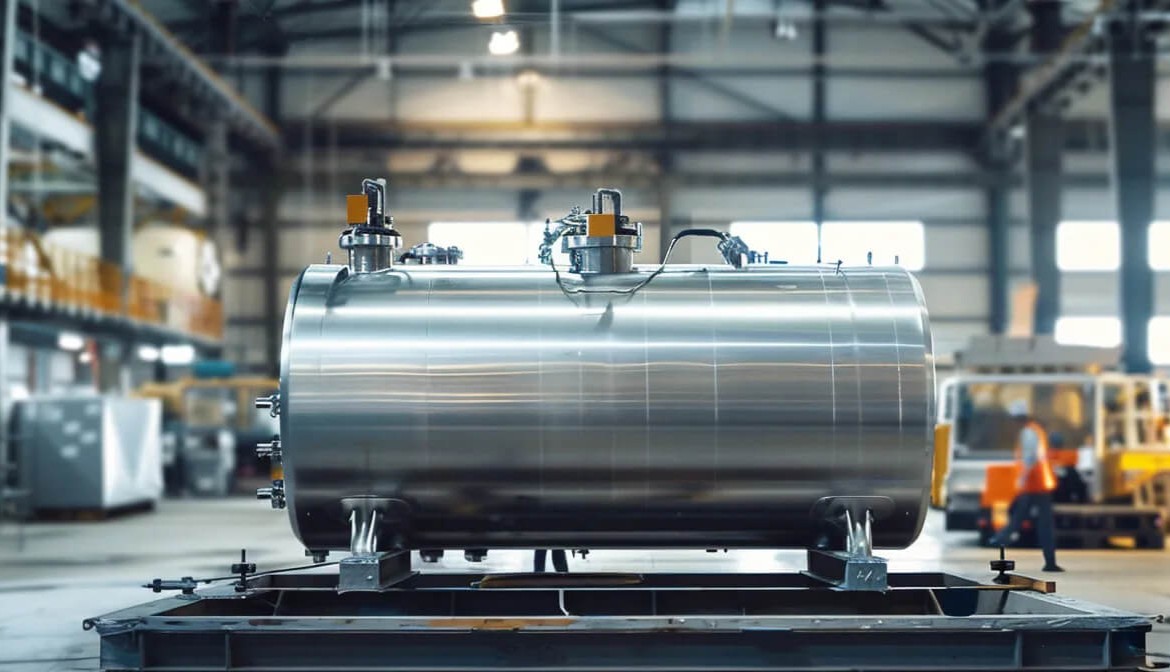

The Durability and Longevity of Stainless Steel Tanks in Industrial Settings

Stainless steel tanks are the preferred choice in demanding sectors due to their unmatched durability and resistance to impact, heat, and corrosion. Their high tensile strength ensures long-term structural integrity even in harsh industrial conditions, making them far superior to alternatives like concrete or plastic. With proper upkeep, these tanks can last for decades, minimizing replacement costs and enhancing capital investment efficiency.

The robust design of durable stainless tanks for industry also helps prevent leaks, spills, and other safety hazards—an essential factor when handling hazardous materials. Advances in manufacturing have further streamlined production, allowing companies to adopt reliable, long-lasting storage solutions that deliver consistent performance and value over time.

Resistance to Corrosion: A Key Advantage for Chemical and Food Processing Industries

Stainless steel’s natural corrosion resistance makes it indispensable in industries like chemical processing and food production. Its chromium content forms a protective oxide layer that prevents deterioration, allowing tanks to endure harsh substances without compromising structural integrity. In food manufacturing, this resistance ensures that acids from fruits and vegetables don’t cause contamination, preserving both product safety and quality from storage to sale.

Chemical facilities also rely on stainless steel tanks for their ability to withstand aggressive compounds that would destroy other materials. Their long-lasting resistance reduces the risk of leaks, contamination, and costly downtime. Stainless surfaces require gentler cleaning agents, helping companies minimize maintenance demands and meet modern sustainability standards.

Stainless Steel Tanks and Environmental Sustainability: A Match for Eco-Friendly Practices

Stainless steel tanks are gaining recognition for their strong environmental benefits. Made from 100% recyclable material, they often contain a high percentage of remelted scrap, supporting a circular economy and reducing landfill waste. Their long lifespan minimizes the need for frequent replacements, cutting down on raw material use and the energy demands of manufacturing—especially compared to energy-heavy materials like concrete.

Beyond durability, stainless steel’s inert nature prevents contamination, preserving the purity of stored materials and reducing product waste in sectors like food, beverage, and chemical storage. Its versatility also supports sustainable industries, with stainless steel tanks widely used in biofuel production, water treatment, and other green technology applications.

Customizability and Versatility: How Stainless Steel Tanks Meet Diverse Industrial Needs

Stainless steel tanks stand out for their unmatched adaptability, allowing industries to customize them in various sizes, shapes, and configurations. From compact vessels for hazardous chemicals to massive silos for grain storage, these tanks can be tailored with precision to meet specific operational needs. Their design versatility supports a wide range of applications, including brewing, food processing, and pharmaceutical manufacturing, where cleanliness and safety are essential.

Beyond basic customization, stainless steel tanks can incorporate features such as insulation, temperature control, and specialized fittings. As production demands shift or regulations change, these tanks can be easily modified without replacement, enabling companies to stay efficient, compliant, and responsive to evolving industrial requirements.

Cost-Effectiveness Over Time: Analyzing the Long-Term Savings of Stainless Steel Tanks

Investing in stainless steel tanks may have a higher upfront cost, but their long-term financial benefits are substantial. Their durability reduces the need for frequent repairs or replacements, cutting unexpected expenses and boosting return on investment. Low-maintenance requirements further lower ongoing costs, as these tanks are easy to clean and require fewer resources. This combination of longevity and minimal upkeep makes stainless steel a cost-efficient choice for industries seeking reliable storage solutions.

Stainless steel’s non-reactive properties also protect stored products, preserving quality and preventing losses from contamination or spoilage—a critical factor for industries with strict compliance standards. Their recyclability and salvage value reduce environmental remediation costs, enhancing the economic efficiency of the investment.

Altogether, stainless steel tanks represent an optimized solution for various industrial applications, standing out for their durability, resistance to corrosion, environmental sustainability, customization potential, and cost-saving advantages. They exemplify an investment that continues to yield benefits, affirming their status as a cornerstone in modern industrial infrastructure.